Spider Crane Lift With Lifting Basket 1 Ton

Spider Crane Lift With Lifting Basket 1 Ton - 1 Ton / 8M is backordered and will ship as soon as it is back in stock.

Payment Way

Payment Way

After we Confirm the model, the deposit can be paid by paypal, or by T/T credit card transfer, etc.

Delivery and Shipping

Delivery and Shipping

Our products are sent from Qingdao port by default, before shipment, all machinery will be loaded with wooden crates and metal plates to prevent rust and corrosion, and then take photos and videos to customers to confirm, according to the agreed time to load the ship!

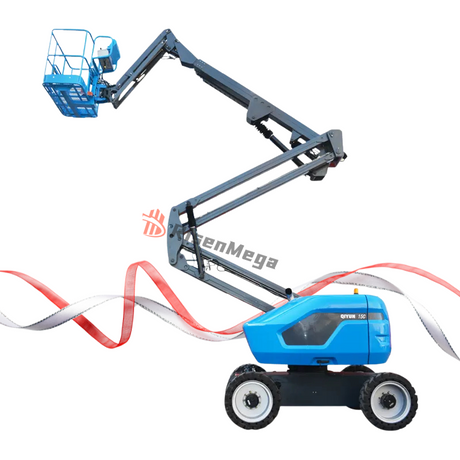

Towable Boom Lift

Q355 Hydraulic Motor, it can support 1-12Ton and fit for narrow base.

Description

Description

To learn more about our Spider Crane products please see our blog!

1 Ton Spider Crane Lift Parameters:

- It is equipped with ± 80° rotating.

- The outrigger is equipped with one-key leveling function.

-

360° Rotary Turntable, Remote control can be added.

- Three-phase AC asynchronous motor.

- Can Customized Aluminum Pockets.

-

Q355D It adopts high strength steel.

Safety System:

- Automatic braking system

- Emergency descent system

- Emergency stop button

- Fuel line explosion-proof system

-

Fault diagnosis system

- Tilt protection system

- Charging protection system

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.